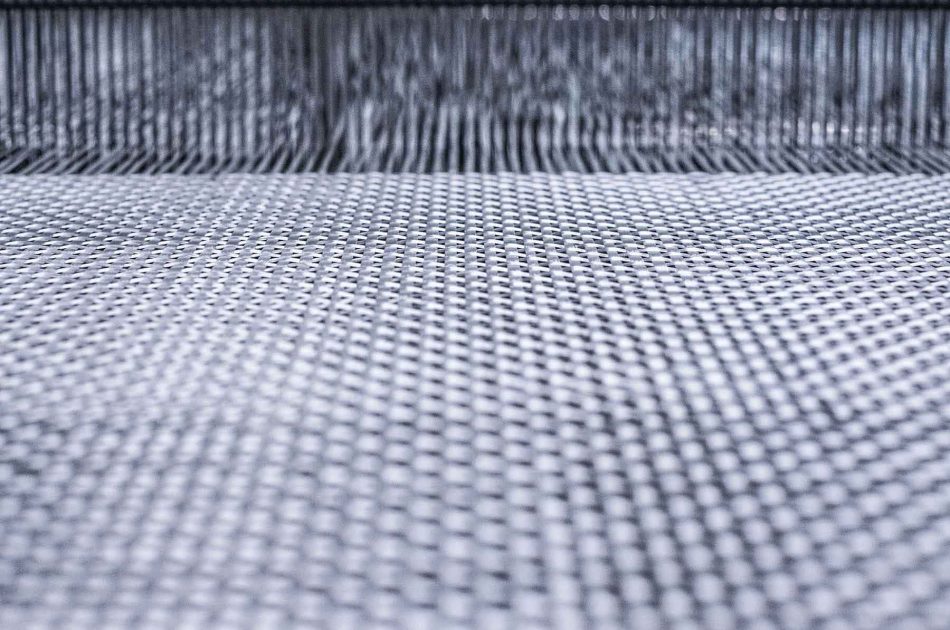

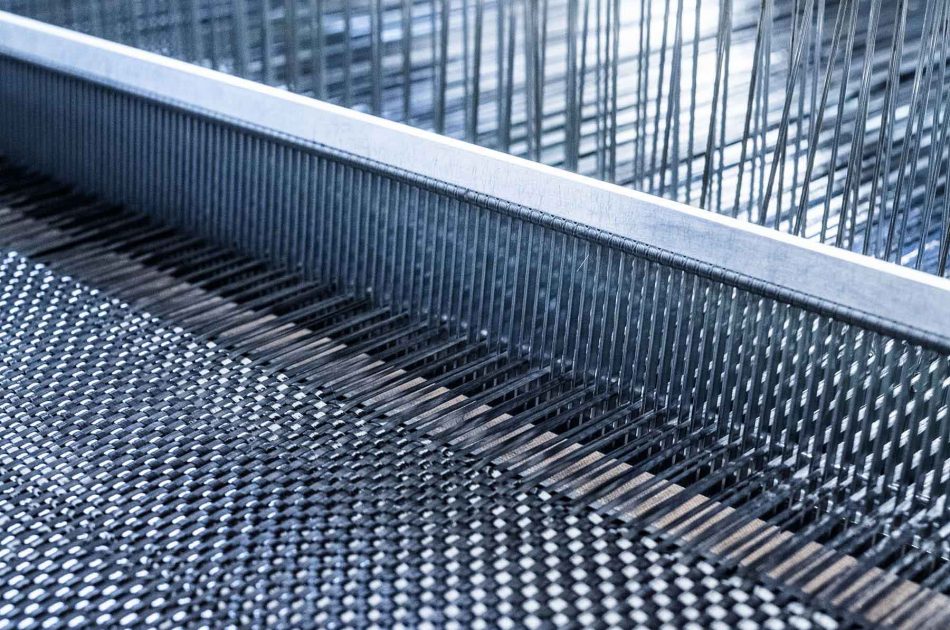

Dipex Woven Fabrics are composed of glass or carbon fibres woven into a crimped bidirectional reinforcement. They are produced by the interlacing of warp (0°) and weft (90°) fibres in a regular pattern or weave style. The fabric’s integrity is maintained by the mechanical interlocking of the fibres.

Woven roving fabrics provide the most economical solution for raising the glass content of composite structures and delivering an increasing overall flexural and impact resistance without adding thickness, weight, or other non-reinforcing materials.

Weave styles

The ability of a woven fabric to conform to a complex surface (drapeability), surface smoothness and stability of a fabric are controlled primarily by the weave style.

TWILL WEAVE

One or more warp fibres alternately weave over and under two or more weft fibres in a regular repeated manner. The twill weave delivers the visual effect of a straight or broken diagonal “rib” to the fabric and reduces crimp. This contributes to a smoother surface and better wet out and drapeability over the plain weave with only a small reduction in stability.

PANAMA WEAVE

The Panama weave is fundamentally the same as the plain weave except that two or more warp fibres alternately interlace with two or more weft fibres. This weave is flatter, and, through less crimp, stronger than a plain weave, but it is also less stable. It should be used on heavy weight fabrics made with thicker (high tex) fibres to avoid excessive crimping.

REINFORCEMENT FIBERS

Dipex Woven Fabrics are made with either E/ECR glass or carbon fibre depending on the final application. Upon request, it is possible to combine carbon fibres with glass or aramid fibres as well.

E-GLASS FIBRES

represent the most common form of fibres used for the reinforcement of composites due to their good tensile strength, stiffness and electrical properties at a relatively low cost. They are characterised by their lower alkali content and a softening point at 850-870°C.

ECR – glass fibers

are widely used to produce fabrics for composites facing corrosive environments. They represent the corrosion-resistant version of E-glass with a higher softening point at 916°C due to their boron-free composition.

CARBON fibers

deliver the highest specific stiffness and a high resistance to corrosion, creep and fatigue. They are known for their very high strength in both tension and compression and are considered to be the strongest of all commercial reinforcing fibres.

Our range of technical fabrics is approved by world renowned certification body DNV to meet the highest composite industry standards.

PRODUCT CUSTOMISATION

Our fabrics are tailored to meet the individual needs of our customers. Product parameters can be adjusted based on the final application in order to deliver the expected performance.

FABRIC WIDTH

Woven fabric widths can be adjusted to the customer’s needs without off-cut. The most common widths for woven fabrics are comprised of 125 or 127 cm. Depending on the client’s preferences, the product width can range from 150 mm tapes up to 3800 mm for glass and from 970 to 1800 mm for carbon fibre woven fabrics. In the case of tapes, for the better fixing of the edges melted yarn can be included.

FIBRE LOAD

For applications requiring a high concentration of fibres and strength in only one direction, unbalanced woven fabrics can be produced using different fibre count and tex. Unidirectional woven fabrics can be produced with up to a 95/5 weight distribution between the warp and weft directions and are available in both warp (UD0°) and weft (UD90°) versions.

SURFACE WEIGHT

Depending on the fibre count and linear density, different areal weights per layer can be designed. E/ECR glass woven fabrics are available in total surface weights between 200 and 1500 g/m2. Carbon woven fabrics range from 200 to 800 g/m2.

ROLL LENGTH/SIZE

The standard roll size is typically 30-50 kg for manual handling. The length of the rolls can be adopted based on the customer’s process needs. For continuous production processes, the product length can be adjusted to more than 1000 linear metres.

RESIN COMPATIBILITY

The glass and carbon fibres used for the production of our woven fabric product range are coated with a variety of sizes to provide compatibility with multiple resin systems.

Unsaturated

polyester

Vinylester

Epoxy

Polyurethane

Polypropylene

FEATURES AND BENEFITS

- Interlocked layers between the fibres help to prevent delamination

- Regular porosity leads to fast wet-out and application

- Crimp engineered to deliver high impact resistance

- Design flexibility due to different weave patterns

- Cost-effective reinforcement to deliver lower finished part costs

- Product widths can be adjusted to customer needs without off-cut

END USE METHODS

Woven fabrics are typically used in the marine, wind energy, automotive, and sports and leisure industries to increase the flexural and impact strength of laminates. They are designed for different end use methods and processes such as:

Hand lay-up

Vacuum moulding

Winding

Compression moulding

Pultrusion

Resin transfer moulding

Pre-pregging

Continuous laminating

SUPPLIER REFERENCES

In order to deliver the best possible solutions to our customers, Dipex directs a lot of attention towards the selection of suitable raw materials. Therefore we source our fibres and raw materials from established and well-known suppliers. Our main references include:

Contact us